The bigger the tire & wheel the more stored potential energy.

For example, a 27.00R49 tire with 102psi has 309,800 ft/lbs of stored energy.

This is equal to moving a 200lb person 6500 feet in one direction.

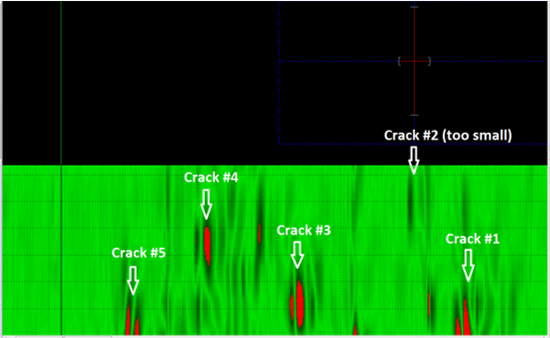

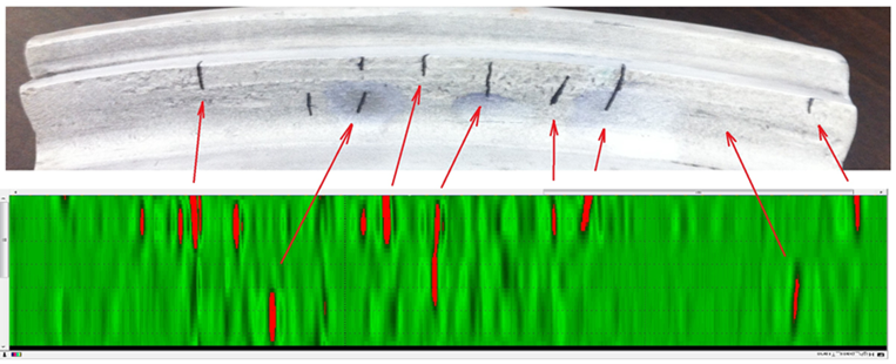

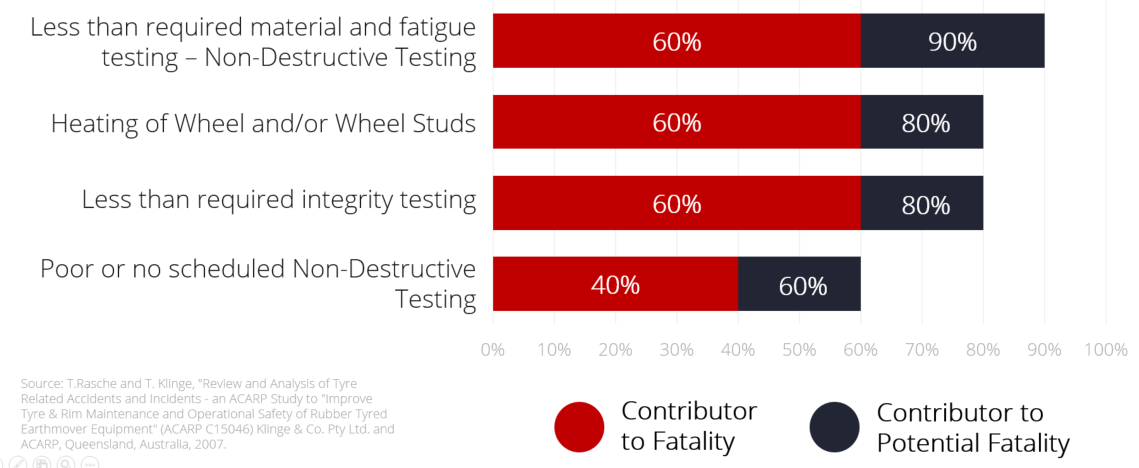

Australia law mandates all OTR Assemblies must be NDT inspected every two years